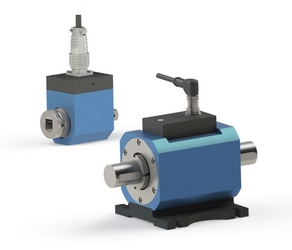

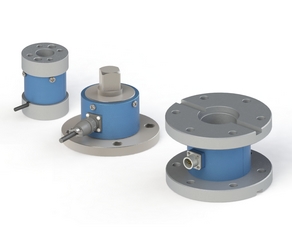

Based on production principles, the load cells have the following types: Piezoelectric load cells, capacitive load cells, pneumatic load cells, hydraulic load cells, Vibrating wire load cells and Strain Gauge Load Cells. Loadcellsensor Technology Corporation Limited produces load cells, force sensors and torque transducers only based on strain gauge technology with Wheatstone full bridge configuration.

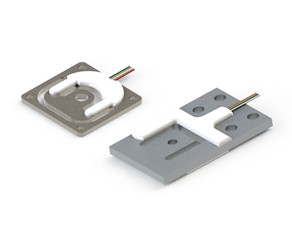

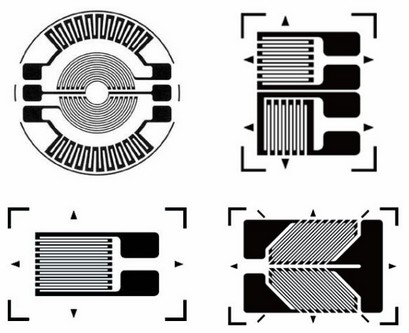

Strain gauges come in a variety of configurations but are mainly constructed of very fine wire, or foil, set up in a grid pattern and attached to a flexible backing which enable is to be easily bonded to a spring material. When the shape of the strain gauge is altered, a change in its electrical resistance occurs. The wire or foil in the strain gauge is arranged in a way that, when force is applied in one direction, a linear change in resistance results which can then be measured as a voltage change. Since this change in output is proportional to the amount of weight applied, the weight of the object can then be determined from the change in voltage.

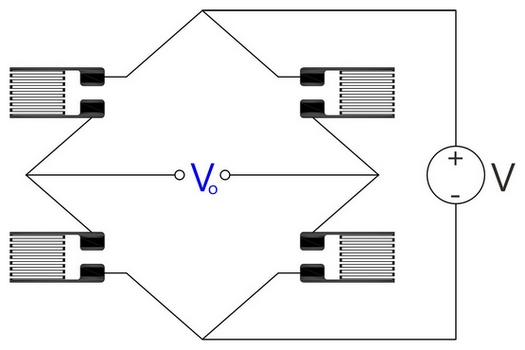

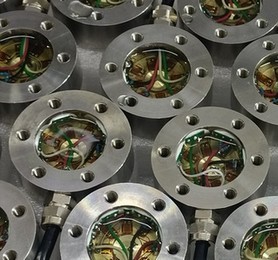

There are many possible permutations of the number of strain gauges, their orientations, the geometry of the load cell, and the strain gauge locations in the load cell. A setup with four strain gages to form a Wheatstone full bridge like above picture shows is the most common. The supply voltage V is a constant DC voltage, the output voltage is measured at Vo. If the resistance of the four gauges is equal, Vo is zero, Vo will change if the bridge resistance changes which happens when the load cell is loaded. The change in Vo is typically very small and is also proportional to the supply voltage V, therefore the rated output (sensitivity) of a load cell is specified as the number of millivolts per volt of supply voltage.

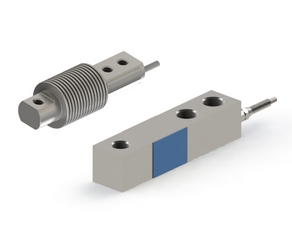

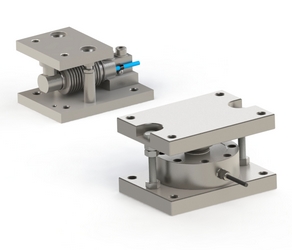

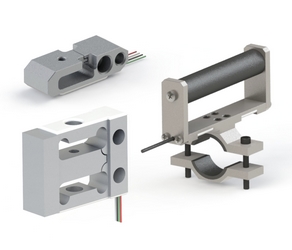

The metal elastic element of load sensors is normally made from one of aluminum, alloy steel and stainless steel, it can be processed into various shapes and structures such as s-beam, shear beam, single point, button type, pancake style, canister and other dimensions. Heat treatment and surface treatment processes may be required for some cases. The strain gauge bonding area needs to be polished to provide a smooth sticking surface. Some models will need extra temperature compensation and Young's modulus compensation to achieve desired accuracy, corner adjustment needs to be done for off-center weighing sensors.

For OEM applications and special measuring tasks, LCS is happy to work with our customers to provide fully customized solutions for weight, force and torque measurement.